Product Overview

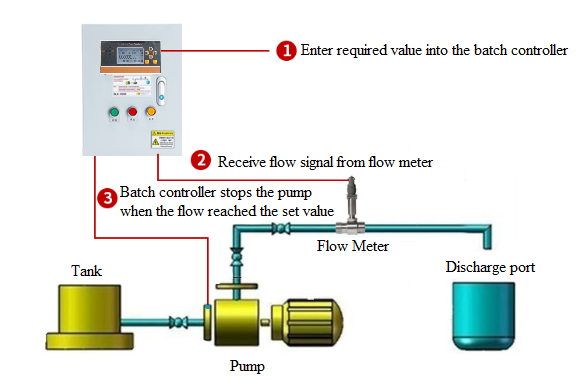

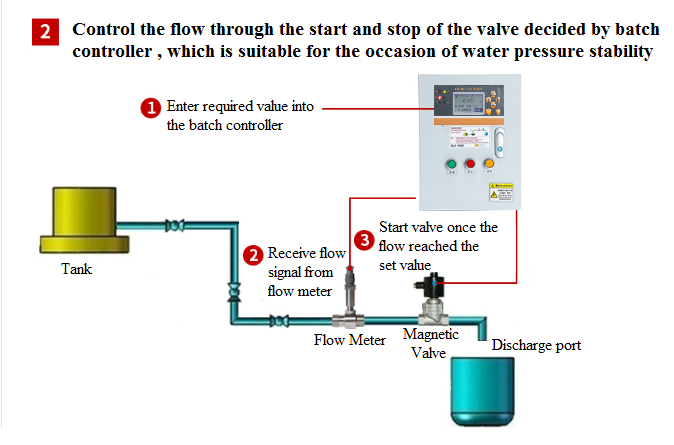

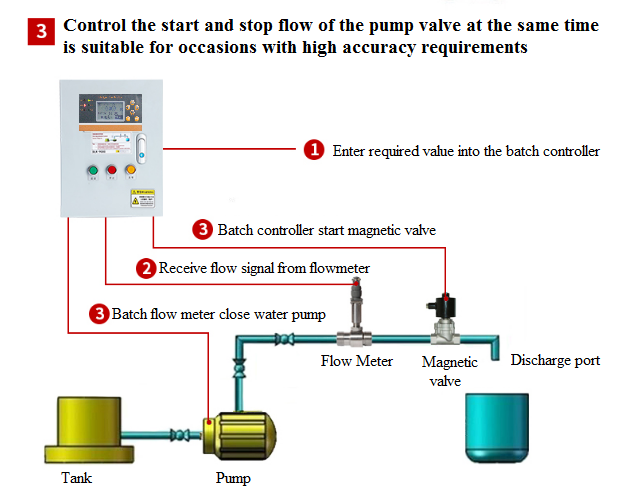

Batch controller instrument can cooperate with all kinds of flow sensors and transmitters to realize quantitative measurement, quantitative filling, quantitative batching, batching, quantitative water injection and quantitative control of various liquids. Thermal printer connect with our controller through RS232 interface to print the batch time and quantity, which is convenient for customer read data.

Main Features

1.The error is less than 0.2%F.S, and it has the function of adjustment and digital filtering, which can help to reduce the error of sensor and transmitter, and improve the measurement and control precision of the system effectively;

2. Flow sensor suitable for current, voltage and pulse output;

3. 3 switch input, for start, recovery, and each accumulated value cleared;

4.Point control output, for large valve, small valve hierarchical control and instantaneous flow limit alarm;

5.Variable output can be instantaneous flow value in the form of standard current, voltage output, for other equipment use;

6.The 8 section linear correction can reduce the nonlinear error of the flow sensor;

7.Instantaneous flow can be chosen according to hour or minute;

8.Transparent,high-speed,efficient network communication interface, to achieve complete data transmission and control between computers and meters. The unique control transfer function enables the computer to control the working state and the output of the instrument directly. The time to read the measurement data is less than 10ms;

9. provide test software, configuration software and application software technology support;

10.With a hardware clock print interface and print unit, to achieve manual, timing, alarm printing function. If the intelligent printing unit is selected, more than 1 printers can be shared by many meters.

Below pictures shows the working process of our batch controller:

Post time: Oct-15-2021